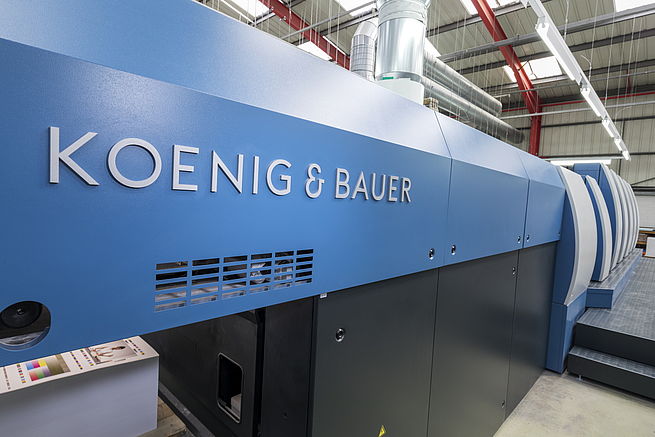

New Rapida 106 Customers DG3/Leycol have hit the ground running with their new Rapida 106 5 plus coater. The new press (ordered in January 2019) was shipped in May and to the delight of the DG3/Leycol management team the press was producing high quality sheets one month later.

DG3/Leycol Commercial Director Nick Wilson stated: ’The installation of the press has been seamless. We are also delighted with the levels of support provided by the service team from Koenig and Bauer. Nothing has been too much trouble for them during the set up and training period and now the press is up and running we are reaping the benefits.’ He continues ‘Our make ready times are already significantly reduced and as the press teams become more experienced they will be reduced even further. The change over from our previous manufacturer was an area of concern for us. However, we have manged this total change of culture without any problems.

On the colour and quality side of things Mr Wilson adds: ‘This is our first press with an inline colour control system and this has made hitting the specifications of the I.S.O. 12647-2 simple. We have just received the prestigious Level 2 “Elite Certificate’ through the BPIF’s Colour Quality Management Certification Scheme which is independently verified by an accrediting body. We are one of a handful of printers to achieve this demanding standard’

Quality and support

The installation of the new press has signalled the start of significant changes at the high quality printers who produce work for some of the strongest brands in the UK alongside the fine art prints they produce for the U.K.’s top galleries. DG3/Leycol can now offer faster production speeds and make readies with the additional benefit of further improving the quality of their highly respected print.

With the additional option of QualityPass they can also produce work which is scored against the requirements of the I.S.O. 12647-2 standard directly from the press. DG3/Leycol Technical Manager Jason Manchester states ‘The work we produce at DG3/Leycol has always to be of the highest quality. We now have the accreditation and all the tools on our Rapida 106 to prove that we can continue to exceed our customer’s expectations’

The smooth start to production stems from a customer focussed approach to the installation from the Koenig and Bauer U.K. team. As with many printers, shift patterns at DG 3/Leycol were a challenge to overcome. Due to the different requirements for training at variable times, a bespoke schedule was created that managed to cover all aspects of press set up, maintenance and colour management equipment. This methodology ensured that now the press is up and running the crews are all trained to an equivalent level and are able to get the best out of all the technology on the press.

To ensure continued high quality output, regular performance coaching sessions have been included in the ongoing partnership agreement. These flexible sessions can be requested by DG3/Leycol once the initial training period ends.

Koenig and Bauer (UK) Sales Director Chris Scully states: ‘It is very pleasing to hear that the installation at DG3/Leycol has gone smoothly and that they are exceeding quality and performance levels. Customers are looking for a firm commitment on support from their suppliers and we always have this as the central theme during the sales process. I am delighted that the hard work and commitment from our service teams has delivered once again.’