• ‘Plus 1’ 8 Colour and double coater started production in March 2020

• Production increased by 25%

• Unrivalled quality control systems

• 'Almost instant response from Koenig & Bauer service team'

Watford, 01.07.21

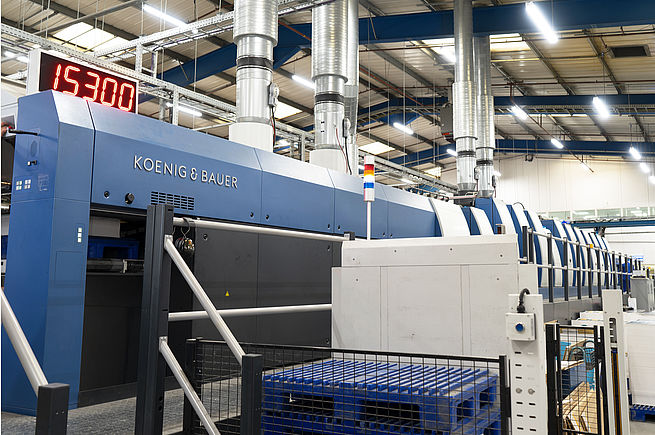

Edenbridge based, the Alexir Partnership has become the latest high quality U.K. packaging producer to invest in a highly specified Rapida 106. The press, an 8 colour with 2 coating units was installed into their Edenbridge factory early in 2020, just as the pandemic was beginning.

The Alexir Partnership is one of the leading names in packaging production, both in the U.K and around the world. They have been operating for over 30 years from 2 production sites in the South East of England. They produce high quality cartons for well-known high street brands and for a range of market segments which include food, healthcare and FMCG (Fast Moving Consumer Goods).

They selected the Rapida 106 after extensive research, field visits and print tests at all the major press manufacturers. The Alexir Partnership is also a member of the International Packaging Group Association which provides a framework for packaging producers to meet and share technical information on packaging manufacturing and best practice.

During these meetings they found that several other members of the group had recently invested in Rapida 106 technology with great success. The press was specially configured to cope not only with their current work types but also to allow the Alexir Partnership to target new markets and to offer the most advanced print options to their clients.

These benefits contribute to the uniqueness of their ‘design-to-delivery’ capabilities in the UK. They are also unique in the fact that they are the only wholly ‘Employee Owned’ major Packaging and Food Manufacturer, having purchased the business from the Shareholders in 2019.

Speaking about the installation, Alexir Factory Manager Andy Crack states: ‘We have become incredibly busy since the press was installed and production has increased by 25% since 2019. The pandemic and the trend for plastic reduction has created a big increase in demand on our carton production volumes. Managing the installation, reorganising the factory to improve the workflow and the restrictions on staffing during this time has been a challenge but we have coped really well. The print quality from the press is very good and due to the quality assurance tools supplied with the press we have experienced a big reduction in quality issues'.

He continues: 'We took one press out and the Rapida has coped not only with the work from that machine but also a big increase in additional demand for our production capacity as well. We have had to invest in new pile turning equipment to keep the press fed with fresh pallets and a good deal of our work is now printed on both sides’.

Commenting on the level of service support Mr Crack states: ‘Throughout the installation and when issues have arisen since, the service department of Koenig & Bauer have provided an almost instant response which is particularly pleasing. We anticipate further growth in business which will increase our impression counts further but we fully expect the press to cope with the extra volumes required from the production department’.

Precision engineering

The Rapida 106 is a special configuration press called a ‘Plus 1’. It features 7 printing units and a coater, 2 drying units followed by another additional printing unit and a final coater unit allowing the widest range of effects and finishes to be produced on a press. The press has a top speed of 18,000 sheets per hour and can print with both UV and conventional inks and coatings on a special sheet size of 780mm x 1060mm. Additionally, the press comes equipped with a whole host of features that enable the highest of performance and quality levels.

Heavyweight performance

The stock range the press can handle is up to 1.2 mm thick and additionally for non-stop running of the thicker stocks produced at Alexir Packaging the press is equipped with an extensive logistics package for both the feeder and delivery and a press raise of 900mm. To aid feeding at the highest speeds, the press is equipped with Koenig & Bauer’s unique Sensoric Infeed System (SIS). For food production, the press has been supplied with food safe oils and greases and will run with food safe inks and coatings.

Make ready automation

For rapid changeovers, the plate changing is fully automatic, with all plates changed in less than 2 minutes and coating forms are also changed semi-automatically in less than one and a half minutes. Colour control is via Koenig and Bauer’s QualiTronic ColorControl inline colour measurement system which automatically updates the colour values after every tenth sheet. For assessment and scoring of the printed results against the requirements of the I.S.O. 12647-2 standard, the press is also equipped with QualityPass software. This software will also provide a trend of the CIE Lab values for each job alongside a whole host of other reports for colour and quality.

Quality Controlled

To provide an extra level of quality to the work produced on the new press it is equipped with QualiTronic PDF which enables comparison of the printed material to an original PDF. Every single sheet produced for each run is compared against the original during running and the operator receives early warning of any defects found by the system.

Data captured

To ensure production is kept at the highest levels, the press software package includes LogoTronic Professional. Signals are taken directly from the press and provide the basis for production monitoring of each job produced. This provides a good overview of press performance and allows the press to receive and send JDF data from pre-press and back into a management information system. Colour reports, maintenance manager and the press colour library are also hosted within this system.

Koenig & Bauer U.K. Ltd Director of Sales Chris Scully stated: ‘We could not be more delighted to have added the Alexir Partnership to our growing list of high quality packaging printers who have made the switch to producing their cartons on the Rapida 106. They have developed a superb and successful business and we are thrilled that we have played our part in their continued growth.’ He continues: ‘Packaging businesses have been put under considerable pressure since last year and have had to work in very difficult circumstances. It is no surprise to us that the Rapida 106 has coped with the increase in volumes and I am also very pleased that our service department has stepped in quickly to support the team at Alexir when they were required to do so.